Answers to the questions that concern all

We make many decisions, though most of our plans will never be implemented. The reasons are simple - first, it is a lack of willpower; secondly, it is the fear of getting bogged down in a whirlpool of problems; and thirdly, it is our usual laziness.

All of our customers are asking the same questions, so we tried to give you, in every section of our website, not "detailed" information about the product, but only the most necessary and understandable to all. In this section, we have collected the most common questions and written answers thereto.

The best proof is an experiment on two rats.

Recently, scientists conducted an experiment, having settled two rats (named Ven and Fan) in two different houses. They built a house made of natural wood for Fan, but for Ven, they built a house made of materials that are used in the construction of modern houses. Before settling in houses, they took the tests in rats, which confirmed good health of both rats. The experiment did not last long and was terminated prematurely, because in two weeks Ven fell into a depression, greatly emaciated and was seriously ill.

During the experiment, Ven was gradually losing its appetite, and then completely refused to eat, his hair faded, timid glance revealed disorder of the nervous system, and tests revealed the presence of large amounts of toxins in his blood. Unlike Ven, Fang not only ate the food that was offered to him, but also gnawed the walls of his wooden house. Fan behaved actively, his eyes sparkled, hair glistened, and tests have confirmed that his body was healthy!

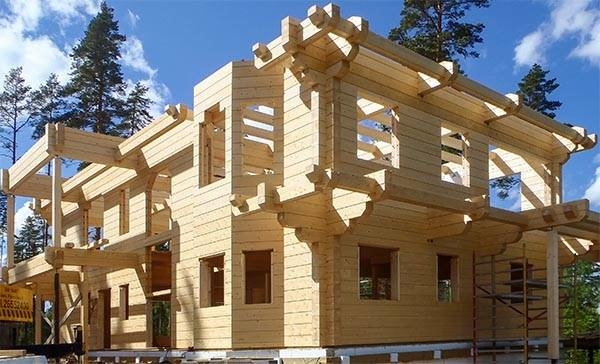

Currently, Europeans like natural wood most of all. This is due to the fact that they have almost no large forest areas – the densely populated Europe has turned today into one big city. Europeans, mostly Germans, have produced and produce now wooden houses but in very small amounts.

First, the historical traditions of wooden houses building, such as in Finland, have not been developed in Germany due to lack of raw materials. Secondly, there was no sense in the development of mass production of such type due to the lack of raw materials and traditions. In addition, German companies do not made houses of a massive glued timber as the Finns do – Germans build their houses of thin boards which are glued together, or do it by old technologies.

Swedes, Norwegians have forests and traditions, but they do not have, for some reason, factories producing wooden houses and, therefore, we export wooden houses to those countries. Thus, the best choice is the Finns – it is not without reason, why they are called ‘loggers’ since immemorial times. Having processing wood for centuries, Finns know it like no other nation: they have exceptional knowledge, the latest technology and the greatest experience.

Anyone who used to go skiing in the Alps, saw the look of wooden houses at mountain resorts in Austria, Switzerland, Italy or France, therefore, poor quality houses with cracks on the walls do not confuse Europeans much.

Furthermore, despite the recently increasing great demand for wooden houses in Western countries, not all Europeans wishing to buy such houses, have seen elite houses of our manufacture. They even find it hard to imagine that the house made of wood can be so elegant!

Wood can save people in case of fire!

Almost everyone is interested in the fire resistance of wooden houses and whether they are treated with fire-fighting products.

Have you ever visited the Central Finland? You can often find here petrol stations built entirely of wood! Wood saves man in case of fire and so they are built here for the purpose of fire safety. Wooden structures resist fire better than other building materials, because the glued wood, even not treated with any fire retardant impregnation, has a fire resistance 4 times higher than that of metal.

In case of fire, metal structures collapse occurs immediately after ignition of the facility, while the wooden beams continue to burn without falling, waiting for the arrival of firefighters.

The advantage of houses of glued beams is that although cross-section of the wooden beam decreases during combustion, but even charring, it keeps its load-bearing capacity for a long time, and does not fall apart immediately, as a welded seam of the metal structure.

Lumi Polar houses withstand 45 minutes of exposure to fire before igniting, and after 60 minutes at t = 1 200°C timber wall is charred by only 10 cm!

The main reasons for high fire resistance:

- Wood of the highest grade (smooth uniform dense structure)

- Super strong glued laminated timber (the strength of the timber is 5 times higher than others)

- Ideal construction tightness (100% imperviousness of houses)

- 100% environmental friendliness (eco-glues, eco-timber and other eco-materials)

The environmental friendliness of the timber is important for fire safety purposes, because a clean, untouched by chemicals tree more than once saved a person in a fire.

From the History of Fires

There are many cases known in the history of fires in wooden houses when their walls had been burning for a long time around people who had been in the house, but man managed to rescue those people. The phenomenon is explained by the fact that the smoke from burning wood does not poison the human body as it happens during a fire in the houses of other materials, when a person dies for 1.5 minutes due to toxic smoke coming from the walls of synthetic materials, solutions, paint, adhesives, etc.

Wooden houses of many manufacturers are treated with fire retardants and other means, but we do not do that because we see no need for it:

- First, the lumber is extremely difficult to ignite.

- Second, fires occurs not from ignition of the walls but from ignition of curtains, wallpaper and fabric surfaces of furniture.

- Third, after treatment with chemicals, wood loses its natural properties and becomes a toxic building material.

- Fourth, any fire is fire - all is burning and spoiling during a fire.

At the initiative of VVT Technical Research Centre of Finland, the fire resistance tests of wooden structures are regularly held at our factory. According to the results of those tests, Certificate of Compliance to SFS-EN 1361-1 Standard - Fire Tests for Wooden Elements - is issued.

Don't ruin!

Do not ruin the wood! Do not soak it in chemicals! Modern wood preservatives contain chemicals which kill in timber its natural properties - such wooden house will not last for a long time. Know that manufacturers treat the wood with protective remedies only to avoid, as long as possible, appearance of cracks, blue and other defects on their houses but the durability of such houses is under a big question.

It often happens that after the manufacturer has processed wood materials with preservatives, the client uses its own impregnation of wood or paint, and they appear to be incompatible. As a result, they become worse, the quality of wooden house deteriorates - paint changes its color, lays down unevenly on the wood surface or peels off, paint stains appear on the wall, etc.

Don't prevent the house from ’breathing’!

Our quality wooden houses are 100% natural because we use, in their manufacture, along with wood, only environmentally friendly products, not only as a waterproofing, insulation and adhesive, but also for other purposes.

In order that your house would remain clean at the wooden house construction site, we spray them with harmless liquid repellent. Therefore, after the assembly of the wooden house, its walls should be sanded. Then, you can leave a noble fir in its original form, or give it a more spectacular view, treating with antiseptics. We recommend not to use other means of impregnation, varnish or paint, because they would prevent your house from "breathing".

Wooden houses can withstand the strongest earthquakes on the planet!

Wooden houses are never destroyed by earthquakes because their timber joints are flexible and flexible “like rubber”! Scientists at Tokyo University in collaboration with scientists at Helsinki University have conducted tests for building resistance to earthquakes. The test results exceeded all expectations! It turned out that the wooden houses of timber, as well as log houses, were able to withstand the strongest earthquakes in the world. Wooden buildings are structurally more flexible and able to withstand heavy loads without breaking.

- When at the beginning of the last century, a devastating earthquake occured in the city of Alma-Ata, it was only wooden houses that survived.

- During the recent earthquake in Italy, all the concrete buildings were destroyed, while the wooden houses have received relatively minor injuries.

- In 2008, Sichuan Province, China, as a result of the earthquake, which brought great destruction, more than 1,000 schools were destroyed or severely damaged. Using wood as construction material may contribute to protection and safety of children in the future.

During an earthquake, the house of timber / logs staunchly resists both horizontal and vertical displacements due to the elastic seals between wooden structures. Elastic design of the wooden house is reliable because of its high resistance to deformation, providing exceptional strength of the house in seismic regions.

Where there are advantages, there should also be disadvantages, and therefore we searched for them for a very long time in our log houses, but we never found them. As it turned out, the unprecedented happens.

Many people, for example, are afraid to build, explaining the place of high humidity and it is absolutely in vain. There is solid water in Finland, water is all around))) Not only is there 190,000 lakes in the country, but it is also washed by a bay. The wood is good because it absorbs moisture and evaporates it. Think about why piers, bridges, jetties are made of wood and everything will become clear...

In general, a tree is supposed to live in nature, and nature has neither bad weather nor a bad climate - therefore, it feels the best in any open air, both wet and dry.

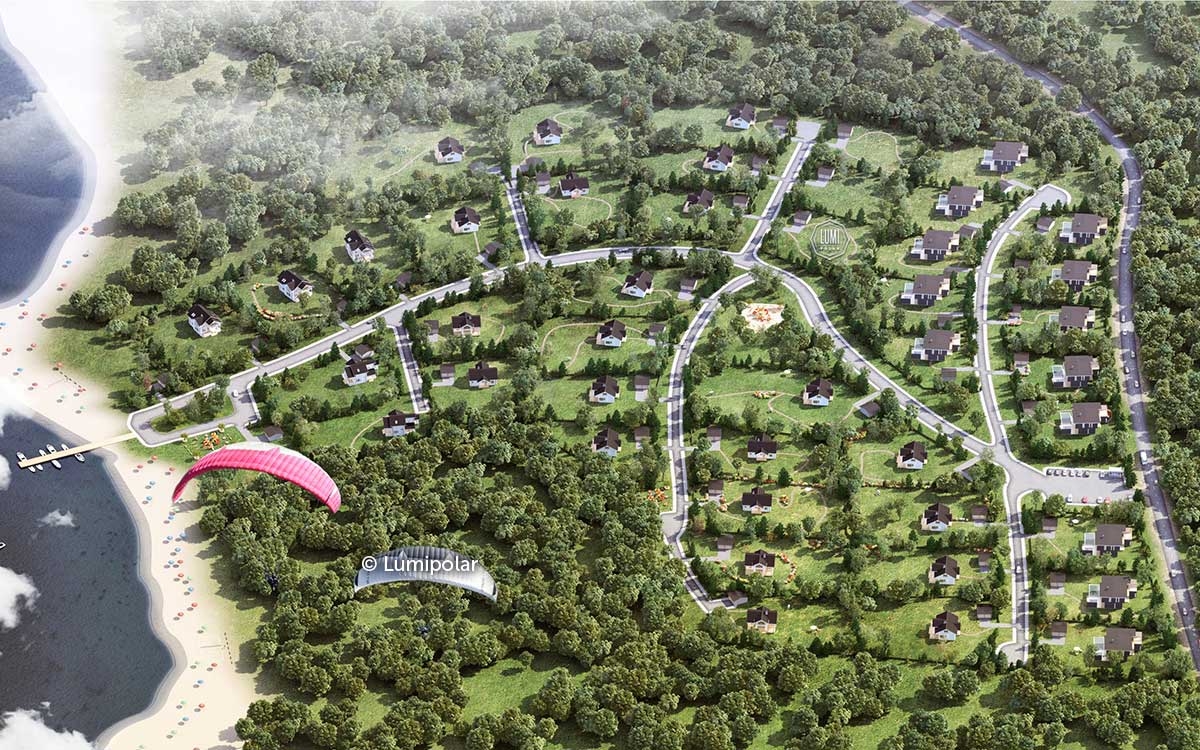

The more people live outside the city, the more civilized that society is considered to be

After interest to appearance and fashion in youth, people began to be interested in their homes. It is very important because our house is our life. If you are thinking about your own home, that means it's time to ask the question: "Who am I?" and "How I want to live?" For example, Europeans tend to live in suburban homes, despite the fact that the road to their place of work in the city may be some tens of kilometers.

There is a perception that the more people live in suburban homes, the more progressive is the country and is considered to be more civilized society.

Because a quiet life in nature contributes to the creativity of creation, while life in the big cities is associated with stress and atmospheric pollution, which leads to diseases and reduced life expectancy? Scientists say that the most serious damage to the body may be caused not by poor quality of food and water but by air pollution – after all, we eat 3-4 times a day, but we breathe every second.

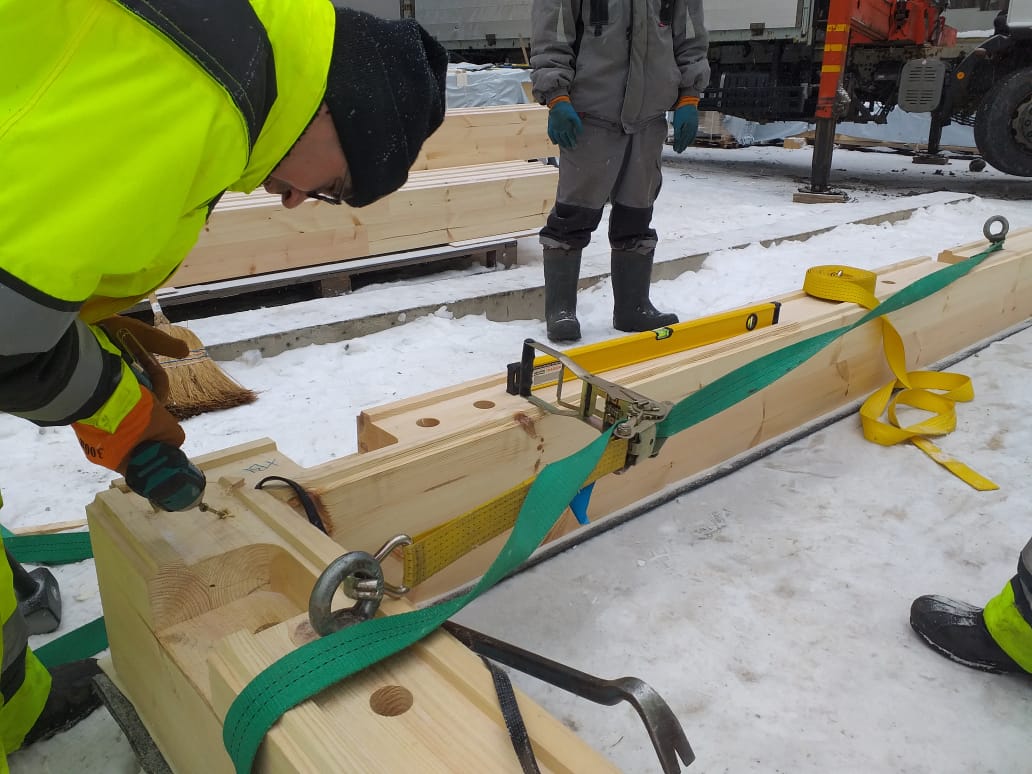

Many people mistakenly believe that the house should be built only in summer

However, it is not true - it all depends on the quality of construction materials. For example, we can build our high-quality wooden houses at any time of the year - weather conditions can affect neither their quality, nor the quality of their construction. If we talk about houses of lower-quality materials, they should be built only in the winter, because then there will be fewer cracks and the buildings will settle down straighter, shrink elements will be bent less etc.

If you choose the season for the construction of a wooden house, you should know that winter has the best climate conditions and some of the benefits for it, for example:

- In winter, the earth and the air cleaner and therefore wooden parts get less dirty ?

- In winter, there is no rain, air humidity is less, so the external environment affects less the well dried wood details

- In winter, the assembled wooden houses settle down more evenly ?

- In spring, it will be easier to equip a house built in the winter – the house interior as well as the landscape of the land plot.

Options of strip or slab foundations are possible. Type of foundation must be selected by a professional - its type depends on the climate of the region, terrain and soil type.

We recommend building houses in Finland from a laminated board with a thickness of 190 mm. When selecting the size of the laminated veneer lumber, you should consider matching the value of the house and the thickness of its walls. For example, wooden houses of large size look better when they are made of thick lumber, but small wooden houses, - when they are made of thinner lumber. Usually, we recommend wooden houses of laminated veneer lumber from 190 mm to 235 mm.

For year-round in France and other southern regions, we recommend the wooden house of laminated veneer lumber with a thickness of 190 mm.

According to the building regulations in Finland, the heat transfer coefficient of external walls in the houses of lumber (U) cannot be more than 0, 60 W / m?K. Examples of U-value for the different thickness of laminated veneer lumber / timber ?:

Lumber of 212 mm - 0,51 W/m?K?

Lumber of 190 mm - 0,56 W/m?K?

Lumber of 180 mm - 0,69 W/m?K?

Log of 230 mm - 0,6 W/m?K?

According to the building regulations in Finland, in Finnish wooden houses without additional thermal insulation, laminated board with thickness of, at least, 180 mm should be used. Our Finnish log houses or Finnish houses of lumber 190 mm without additional insulation are being built even in the Far North, where temperatures reach 50 degrees.

It is worth noting that in addition to the thickness of the walls, other factors affect the heat retention in a wooden house of laminated veneer lumber. Whatever the thickness of the lumber house is, if fitness of its parts is low, there will be no warmth in such a wooden house.

We use more advanced technology in our wooden houses - we lay down a vapor-permeable sealing strip along the length of all crowns, and then, under their weight, the strip will expand to fill all available space. Thus, the joints are tightly closed against access of air and moisture.

In addition, most of the heat goes away, naturally, in upward direction, therefore, a properly designed roof and insulation installed in it, are crucial for keeping warm in a wooden house. Windows, especially with a large glass area, are important for keeping warmth in the house of laminated veneer lumber. Therefore, windows should be of high quality.

We use two types of impact-resistant protective glass in our wooden houses: they are: tempered glass and laminated glass –Triplex. That tempered glass is glass which is heated to a temperature of 650 degrees, and then rapidly cooled. Through this process, the strength of the glass increases by 5 times.

Triplex, laminated glass, consists of two glasses between which the plastic film is set at a high temperature and high pressure. Triplex Glass looks as transparent as ordinary glass, as refractive index of the film is the same as that of the glass.

The thickness of the glass is not greater than usual one, and it has its protective properties due to laminate. If the glass breaks, the plastic film holds the glass pieces, not letting them fall apart - glass remains in the frame, and the risk of injury is minimized.

We build lumber houses of 2 types: from shrinkable and non-shrinkable lumber. Non-shrink lumber houses are houses of new generation based on advanced revolutionary technology, the advantages of which you can read in the section “15 Indisputable advantages of our houses”.

The settling of our settling Finnish wooden houses of glued timber is approximately 1 cm per 1 meter of wall height, it doesn’t affect the interior finishing in any way - it can be done immediately during the construction of a wooden house.

It is better to make interior walls as a framework because the outer timber has a higher moisture content than the inside one. Humidity of the outer timber amounts to 16-18%, humidity of the inner timber is 6-8%. Due to the fact that the inner layer of timber dries more, skewness of overlaps may occur. Also, in the version of the wooden frame, house has a better sound insulation; also, frame walls are cheaper than walls of timber.

When decorating a wooden house inside, we recommend isolating the premises with high humidity in such way: to put brick inside and outside the wooded walls, leaving a gap of 30 mm between them.

Under the pre-cut technology, wooden parts of the eco-house (a frame house with environmentally friendly natural insulation) are made according to a predetermined size and then assembled on-site, as in the children's constructor.

We do not recommend using a traditional lining outside the eco-house, but the thin laminated veneer lumber or non-laminated timber with thickness of 88 mm or 113 mm. In this case, it will look like a square log wooden house; In addition, timber undergoes bad weather conditions much better than the thin lining.

Despite the fact that in terms of moisture content, use of timber within inner sides of the building is less risky, however, we consider that it will be better using timber from the outside, because, if we consider all in complex, the following benefits will emerge:

- Lumber, placed outside, withstand weather conditions better than panels.

- The house will look like a square log wooden house, and the house can be more easily installed.

- There's no difference for inside of a wooden house, either it will be a lumber or a plate looking like a lumber, because inside, there are not much visible severs.

- That design of the house is cheaper.

Initially, a set of building materials for the eco-building will be cheaper than a set for wooden house of lumber or logs, because it consists of a smaller volume of wood. But the cost of construction of an eco-building is higher than the cost of construction of a lumber house, due to the fact that the thermal insulation should be installed in all the walls of the eco-building, and then internal panels should be mounted. It requires additional materials, time and work and hence, it requires more costs.

As a result, the cost of a turnkey construction of a lumber house and the cost of a turnkey construction of a frame house will be almost identical.

Choose with your heart!

No matter how much we argue about the quality of housing and real estate prices, the choice between an apartment in the city and a house in nature should be made with your heart. You cannot imagine how our customers thank us for truly elite wooden houses built by our company. We became friends with many of our customers, so we know what they say: "We did not feel so good and did not live in such comfort never before. What a smart house and what elegant white wood - one smell of it does worth something!"

Dear customers!

Whichever choice is made by you, the only important thing is that your choice would be correct. And we will wish you to enjoy your future home in the same way as all our customers do. Welcome to our friendly and reliable Finnish company Lumi Polar!