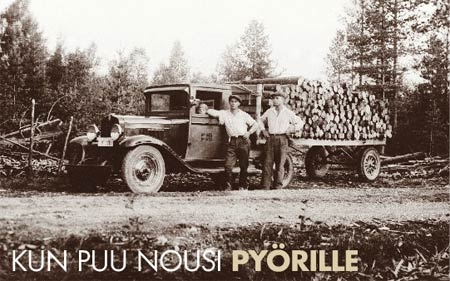

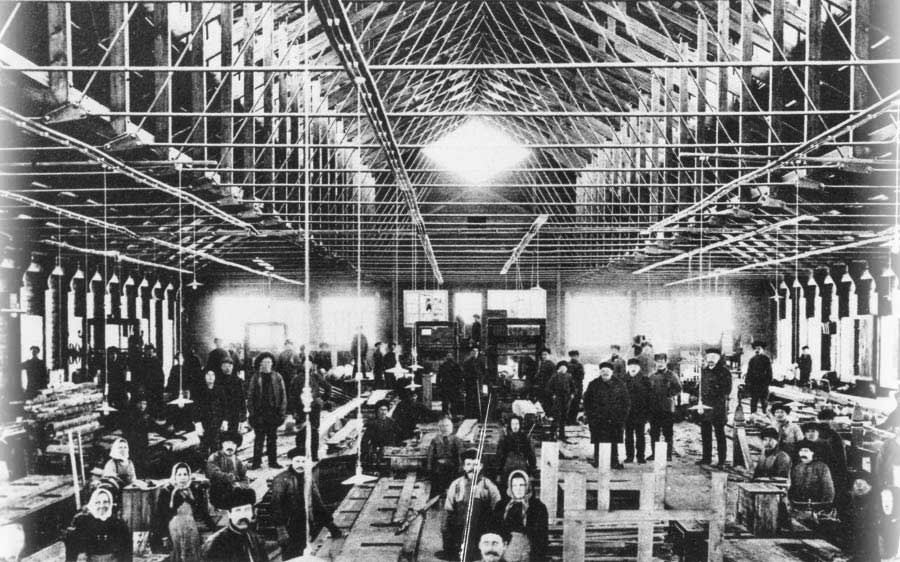

The sawmill started by the Perälä brothers increased by several times. The father of the Lumi Polar Company is a small Finnish family-owned business in the small town of Alajärvi that at the beginning of the XX century had bought a sawmill with the equipment for surfacing wood.

History Lumi Polar

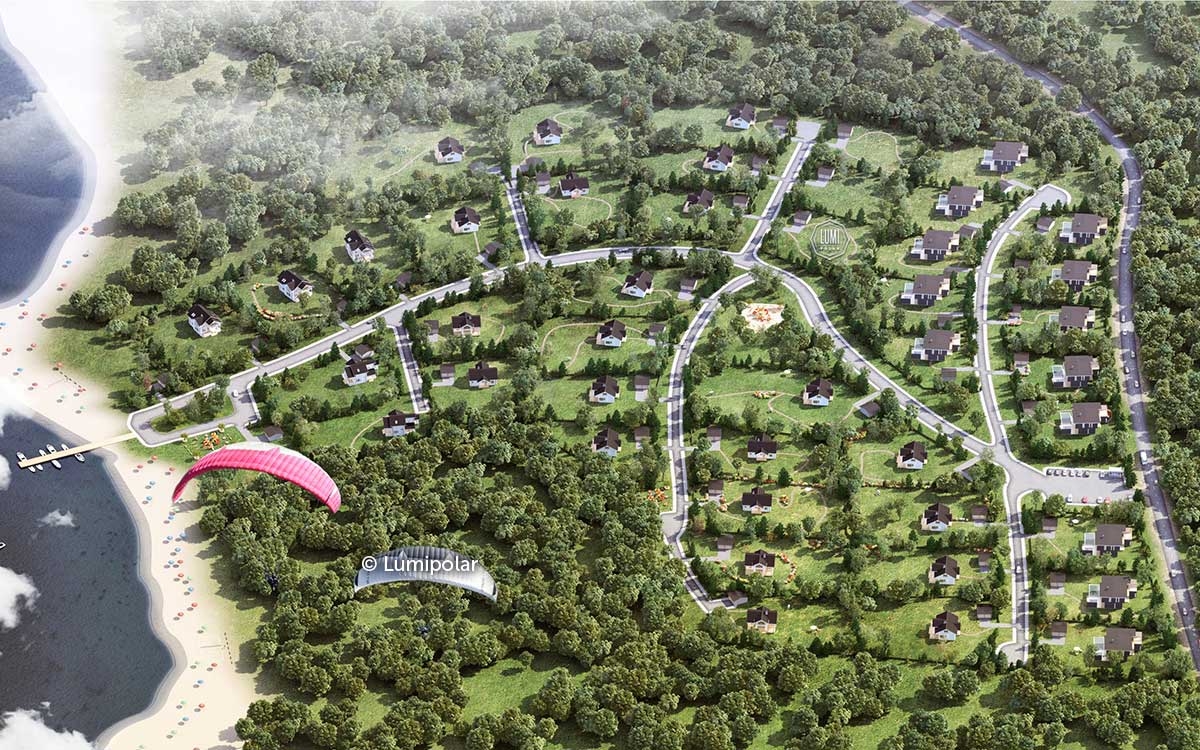

The history of Lumi Polar company is the history of creating high-class ecological world

-

1918Old wall hand-cutting

1918Old wall hand-cutting -

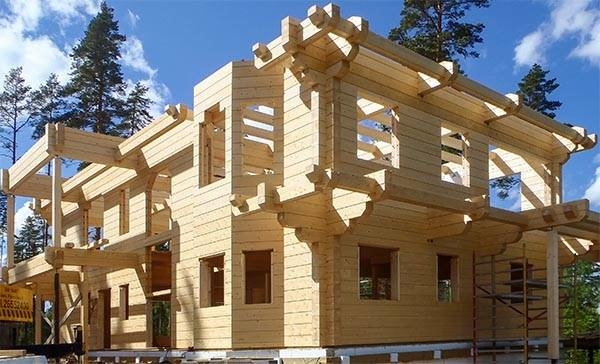

2018Modern perfectly treated timber

2018Modern perfectly treated timber

-

1918

-

1922

With increase in production and personnel the company was restructured into several plants and renamed as Hoiskon Saha. The company was among the first in Finland to carry wood products by road.

-

1940

Lumber manufacture was started at a plant in the town of Seinäjoki at the time when the country faced a need for prefabricated buildings and their long-distance transport. For the tight loading and easy transport considerations logs were re-sawed and delivered to a construction site.

-

1950

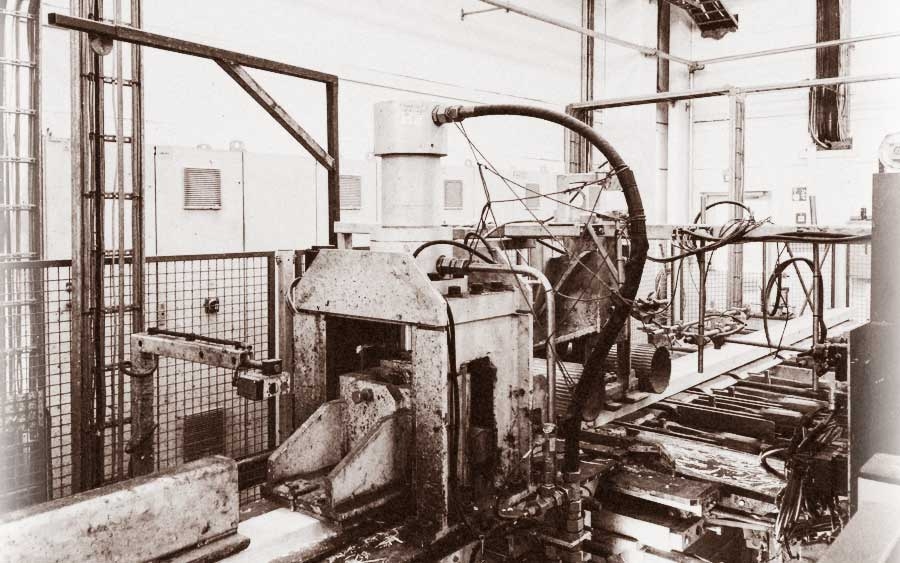

Manufacture of shaved lumber appeared to be a technical innovation. The other works such as making holes for dowels, corner halving, etc. were still performed manually.

-

1960

Lumber profile and bowl shape sawing was mechanized.

-

1975

Manufacture of the first glued wooden structures with the development of industrial chemistry and commercial manufacture of various types of glue. Filing off corner halvings, grooves and daylight openings was initiated and houses started taking on a nice external appearance.

-

1980

Milestone in the company’s development. We were the first in the wooden housing construction business to manufacture houses from laminated lumber and timber and thus founded the industry of glued laminated wood.

-

1993

Entry to the international market. Houses are built in Russia, CIS countries, Germany, Spain and other European countries.

-

1995

Construction of large projects in Kazakhstan (Almaty, Astana) based on integrated approach - 15 lux residences of more than 1000 m2 and site visits by the leading Finnish architects and engineers. We were chosen by the top VIP officials of many countries.

-

1996

Modernization of production and introduction of the latest technology. We were among the first to buy state-of-the-art machines Hundegger K2. Control system mechanisms convey wood materials and house elements from laminated lumber to machines for processing with accuracy to one millimeter. Universal cutters, boring and drilling units of Hundegger K2 machines make it possible to manufacture sophisticated elements.

-

2000

Introduction of a timber-framing technology well-known in West Europe. The company-introduced technology was not based on the simplified German standards. Lumi Polar used solid laminated lumber with due account for its use in harsh climate of the Nordic countries.

-

2001

Development of square corner-shaped durable connections enabling a shift from traditional wooden houses with protruding crowns to fiercely modern buildings. Careful selection of raw material and manufacture of houses from premium quality A and B grade Finnish softwood.

-

2002

Start of the new technologies - large-span wooden and metal beams. The connection of different materials in the construction of the house allowed to create masterpieces.

-

2002

The new shape of timber - Wave Shape - is a reliable protection of the house from external influences, ideal aesthetics. Thanks to this development, the elegant profile closes the “seams” between the crowns (moisture and rain do not get into the joints), the density of the fit of the beam has increased, and the elegant design has excluded any decoration of the houses - all the walls are beautiful in themselves: they look neat, seamless, monolithic

-

2004

Beginning of construction of the unique more than 2000 m2 projects in the mountains of Azerbaijan.

-

2007

Shift to phonic acid and formaldehyde free natural glues that do not cause any harm to health. With the advent to these unique non-toxic glues the durability and strength of glued structures has increased by 5 times!

-

2008

Use of energy-efficient glass and sealers with thermal conductivity less than 0,9 kW/m2 in large glazing area houses.

-

2010

Models and collections of houses in the minimalism style developed. Experiments, new technological solutions development, combination of laminated lumber with glass elements from floor to ceiling. Construction workmanship quality was brought up to perfect.

-

2012

The new technical solution - One Line - is an exclusive feature of our houses: the beams at the corners are joined not in an overlap, but in one line. After the introduction of One Line, houses made of massive timber began to look even more stylish and elegant, and due to a clear tight fit, there was no need for extra flashings and platbands

-

2015

Construction based on challenging architectural projects and designs where sophisticated laminated structures are combined with solid lumber of various section and natural rock. Construction of the world’s largest and sophisticated wooden building 5000 square meters in area.

-

2016

Introduction of revolutionary non-settling technology (houses now do not settle). The basic principle: non-standard bars from arctic tree species growing in Finland beyond the Arctic Circle (they have a dense structure - they are stronger, less prone to cracking) are glued into the center of the beam. Due to the peculiar sawing of fibers, the method of location and cross-gluing, they create solid stiffeners that prevent settling of the building.