A tree turned up to the sky: multistorey housing

Most people, when they hear about wooden houses, immediately think of small one- or two-storey houses. Meanwhile in many countries and, of course, in Finland the industry of wooden multistorey construction is developing quickly. It became possible due to the new CLT technology – (Cross Laminated Timber). These are massive panels consisting of several layers of boards which are crosswise glued. Thus, the high-rise buildings can be mounted from ready blocked CLT modules which are assembled at the factory.

Historical note:

The panels from glued laminated veneer started being manufactured in the 1960's and were mainly used for beams and racks production. The boom in CLT production took off in XXI century. In 2010 the authorities allowed to construct wooden houses up to 8 floors. The first factory which started manufacturing the module elements opened in Kuhmo in 2014 and in two years after the second one was opened. It didn’t take long and in 2015 the first 8-floor wooden house called Puukuokka was built in Jyväskylä designed by Finnish architect Anssi Lassila (OOPEAA buerau).

It is far not the limit for the CLT panels and the storey level will be gradually increasing. Such panels break new ground in history for truly green building.

Fire, cold, earth tremors

The most common questions about wooden houses are concerns about their fire-safety, warmth and strength. Fire endurance of CLT panels can be compared to Ae concrete or bricks: the panels do not burn, but become charred. An experiment has been carried out in Austria – a bonfire using 2,5 tons of firewood panels was made in the box of 60 m3. After an hour, the external side of the panels was warmed only 10oC.

Heat-shield performance of CLT panels is 35% higher than of whole timber or laminated log. In the meantime, they do not absorb moisture, such as, for example, AE concrete. It is also important that such houses compared with brick or monolith houses are known for outstanding system of lateral load resistance and therefore, earthquake resistance. In Japan the 7-floor wooden house built using CLT technology was extensively tested on the biggest seismological equipment in the world and the house survived 14 sequenced quakes measuring 7-8 on the Richter scale without almost any damages!

Good looking, practical, comfortable

CLT technology is a true «gift» for the architects because it allows to build a house in any form and necessary style. The exterior finish of the house is made of facing thick boards or using traditional curtain walling. Interior works are not needed as the material was perfectly prepared and gives an impression of luxurious finish coat. Saw cuts for engineering systems are also made at the factory. By the way, with the same perimeter the inner space of the houses built with CLT panels will be bigger by reducing the wall thickness.

While processing CLT timber, it is glued only with 100% organic glue which doesn't consist of formaldehyde. The construction of the house with the help of 4-5 people brigade speeds up up to 4-5 floors a month! And that's truy the technology of the future.

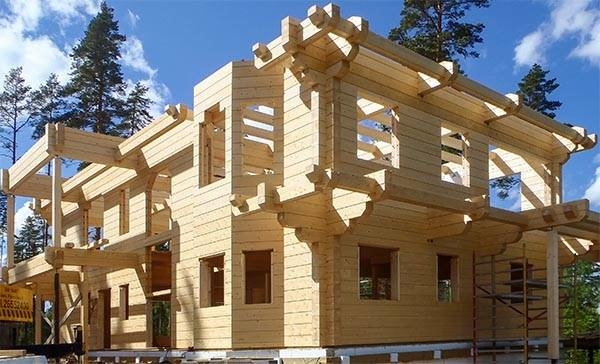

Lumi Polar non-shrink log

CLT technology is widely used while producing LP logs – two thick boards of coniferous woods provide excellent strength and durability of our houses. There is no shrinkage. There is no need for shrink gaps, jacks installation, platbands or molding. Wall docking lines remain perfectly smooth and you can start interior works already at the stage of construction. Non-shrink technology is perfect for the houses built in modern design using “Modern corner”.

We choose the best materials and technologies for our projects – and, of course, for you! Maintenance-free house – what can be better?